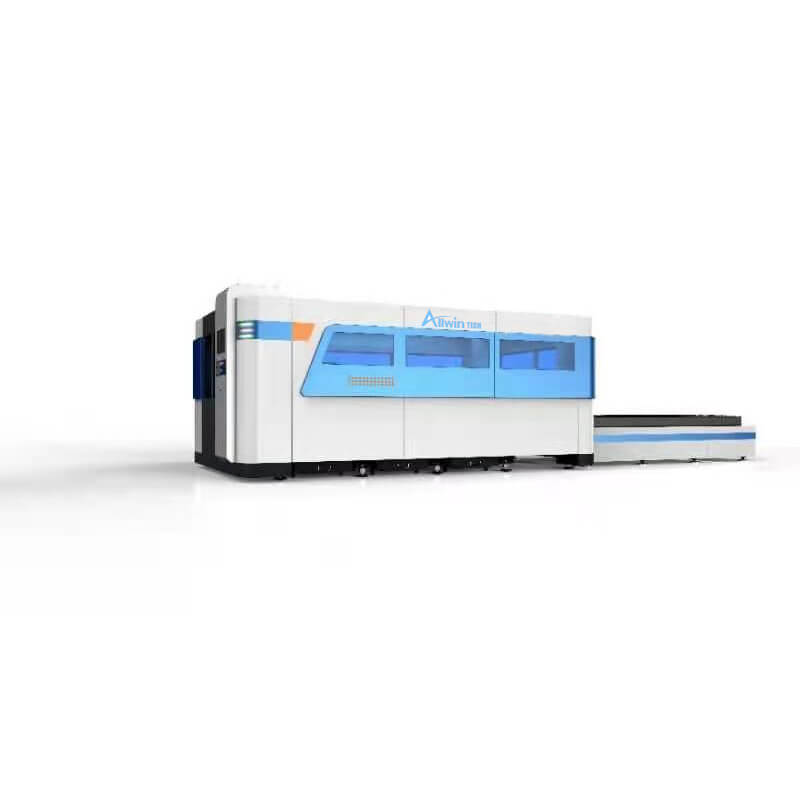

Exchange worktable fiber laser cutter with full cover

- Home

- Products

- fiber laser

- Exchange worktable fiber laser cutter with full cover

Introduction for Higher power 6000W Fiber laser cutter 2m*6m

The fiber laser cutting machine is equipped with an automatic exchange platform,

which can feed the laser equipment at the same time as cutting, and the feeding and cutting are both correct, which improves the work efficiency especially to thick metal sheet..it could save a lots of Labor cost.

Large format fiber laser cutting machine with full cover 6000W/120000W

High quality Full cover 12KW fiber laser cutting machine become popular more and more along with requesting cutting quality higher and higher.

This laser cutter is suitable for metal fabrication such as carbon steel sheet, mild steel plate, stainless steel sheet, alloy steel plate, spring steel sheet, iron plate, copper plate.

We can design and produce laser cutting machines with different fiber laser source 1500W 2000W 3000W 6000W 12000W.

basic information for Exchange worktable fiber laser cutter with full cover

| Model: | 1560 |

| Category: | Exchange table fiber laser cutter with Full cover |

| working Table | automatically Exchange betwen Up and down Flatform |

| Laser source | 6000W/12000W for option |

| Advantage | Full cover to avoid air polluction and improve safety |

| Standard Price: | $70000.00 / Set |

| laser head | Laser head Raytools BM115 for 6000W; Cypcuts Laser head |

| Supply Ability: | 50 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| Payment Terms: | T/T,L/C |

Why choose Exchange worktable fiber laser cutter with full cover?

Let us firstly figure out what concept for higher power Exchange worktable fiber laser cutter with full cover?

What is higher power?

Higher power is pointing to Fiber laser generator(Fiber laser source).

Normally speaking fiber laser source is including 1000W,1500W,2000W,3000W,6000W;10000W and 12000W.

High power is meanning to 6000W 10000W 12000W 20000W.

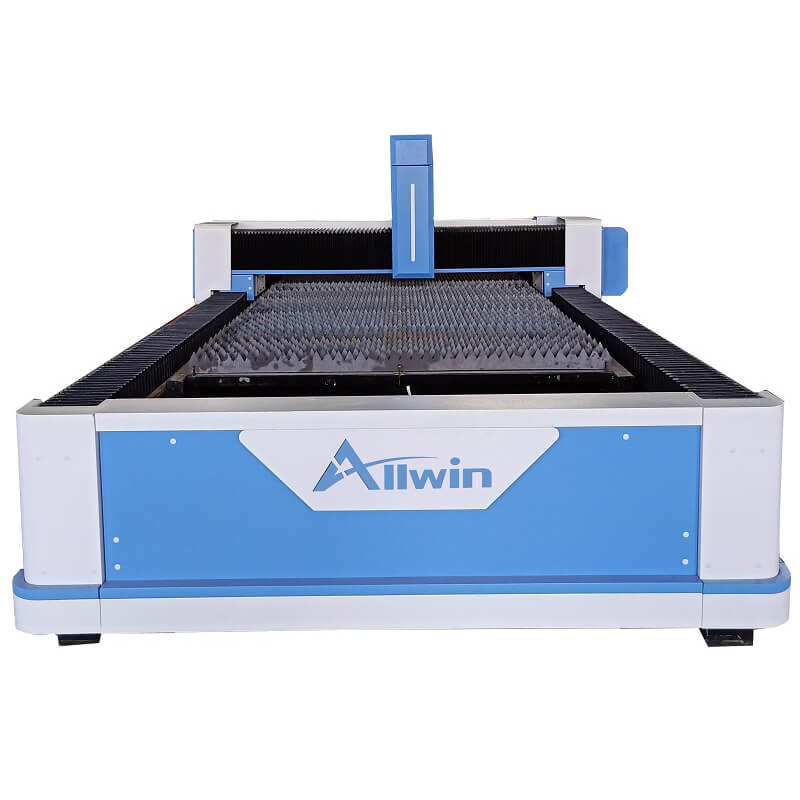

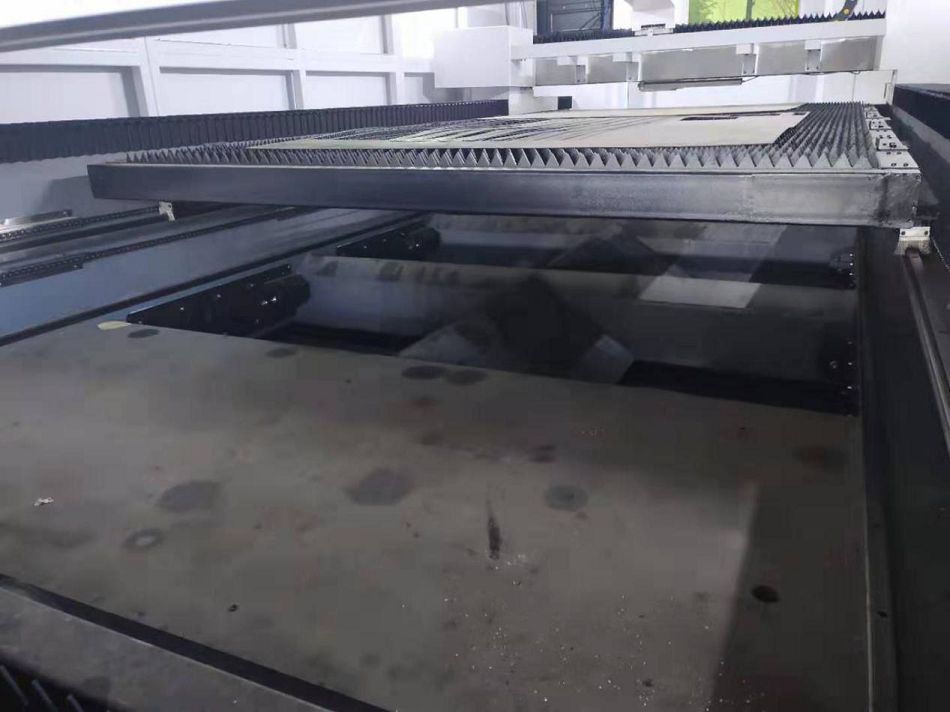

What is Exchange worktable fiber laser cutting machine?

Exchange worktable means has two interchangeable work pallet and One work table is in cutting,another work table could be loading and unloading to save your time.

Exchange worktable has up and down exchange platform has same cutting function as the general fiber laser cutting machine.

most of fiber laser cutting machine has one worktable which can not exchange at all–We call it Single worktable laser.

For single worktable fiber laser cutting machine you have to unload metal sheet after finish cuts .which waste time

Exchange worktable fiber laser cutter brings very convient thick metal plate.

up and down exchange platform fiber laser cutting machine could load the material without stopping the cutting work which improves the machine Work efficiency.

Why need add Full cover?

with Full cover could protect operator workers safety and reducing noise and seperate dust.

Dual platform switching system for cutting bed to save feed time.

Save more than 50% space, improve space utilization;

The exchange time of the front and rear platforms only needs 15 seconds, and continuous cutting processing can be realized.

| Model | LD-1560 |

| Working Area | 1500mmx6000mm |

| Brand | ALLWIN CNC |

| Laser Power | 6000W RAYCUS fiber laser |

| laser head | Swiss RAYTOOLS with auto focus |

| software | Professional FSCUT2000 with Cypcut software |

| motor and driver | Japanese YASKAWA servo motors 1300W |

| Reducer | Japan SHIMPO reducer |

| Water chiller | S&A brand with Dual temperature,dual control |

| Rack and pinion | Taiwan brand T-WIN rack and pinion |

| Guild rails | HIWIN GUILDER RAIL |

| Exhaust fan | Blower Exhaust fan |

| Air compressor | YES |

| voltage stabilizer | YES |

| Cutting Thickness | 0.3-30mm (According to different fiber laser ) |

| Max Cutting Speed | 40m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Transmission | gear rack double driver |

| Machine Structure | General machine frame or Heavy duty frame |

| Machine weight | 2100kg |

| Power Requirements | 380V/50HZ/3P (220V Avaliable) |

for one table working, the worker need load the metal sheet to another table, cutting one by one

to save feeding metal sheet and saving labor cost.We need use automatic exchange worktable fiber laser cutter.

In order to reduce the damage to the work table during laser processing, We modified the new work table and added four supports, which doubled the service life of the work table of fiber laser cutting machine.

Based on heavy duty table and it is more suitable for high power fiber laser, especially the high power fiber laser whose power is more than 12000 watts. The addition of a bed helps to increase the cutting speed of the machine. High strength, stability, tensile resistance, guarantee 20 years of use without deformation;

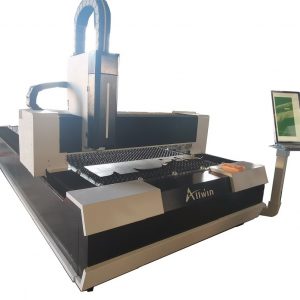

Higher power exchange work table fiber laser cutting machine 6000W with full cover and water chiller 6000

Fiber laser head BM115 for High power laser cutting machine 6000W

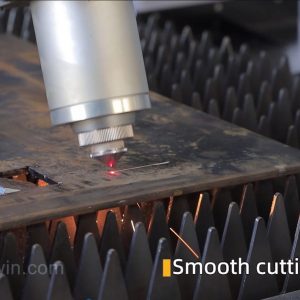

High speed piercing and punch..Its Acceleration is 2.5G and cutting speed could upto 10m per minutes for thin metal plate.

for thin metal plate use rapid performation and for thick metal sheet could work large quantities processing.

Stable perforation,faster operation,easy operation and time saving and labor saving.

Application Industries of High Power Fiber Laser Metal Cutting Machine?

Dual-Purpose exchange worktable fiber Laser Cutting Machine for Metal Sheet and Tube is suitable for aerospace manufacturing.

precision parts manufacturing, automobile manufacturing, ship manufacturing, subway accessories, electrical appliances manufacturing, elevator manufacturing, all kinds of machinery production, elevator manufacturing, metal craft products, advertising decoration and other small business industries.

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

1. Cantilevel Mechanical construction, multi-function for cutting metal sheet and tube, convenient to change working table, it is not only able to cut round and square tube, but also can cut holes on the molding box.

2. Cut lines and holes with different diameters from different directions.

3. Cut inclined section at the end of the pipe.

4. Cut branch pipe intersected with the main circular pipe.

5. Cut squre hole, waist-shaped hole and circular hole on the pipe.

6. Cut all kinds of graphics on the surface of the square pipe.

7. Cut different size of metal sheets.

8. Cut holes on the molding box.

Higher power fiber laser cutting machine 6KW/12KW

1. Automatic focusing, intelligent alarm system, automatic lubrication system

2. Realize the cutting of ultra-fine holes, support three-level perforation, segmentation or progressive combination, and the proportion of small hole processing range can be reduced by about 0.3mm (the thickness of ordinary steel plate is more than 4mm)

3. Support dual-platform fast exchange system (optional), fast cutting speed.

4. Z-axis automatic tracking system, equipped with a capacitive non-contact automatic tracking system, which can automatically adjust the focus to ensure the effect of genuine cutting

5. Using the machine tool with side guide rail structure, the vertical surface bears weight vertically and is not easy to be deformed

6. Laser interferometer correction and compensation, positioning accuracy can reach micron level

7. The spot quality is good, the material deformation is small, the appearance is smooth and flat, and beautiful.

8. Adopting imported servo motor and guiding transmission mechanism, high cutting precision.

9. Use professional software to design all kinds of graphics or text at will, with flexible processing, simple and convenient operation.

10. High stability, using imported light laser (optional), stable performance, the service life of key components can reach 100,000 hours, and the laser is maintenance-free.

11. Lower maintenance cost, no laser working gas: light transmission, no need for reflective lenses, which can save a lot of maintenance costs.

12. The product is easy to operate and maintain, light transmission, no need to adjust the light path.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.