Plasma Cutter with Drilling Machine

- Home

- Products

- CNC Plasma Cutter

- Plasma Cutter with Drilling Machine

why use plasma cutter with drilling machine

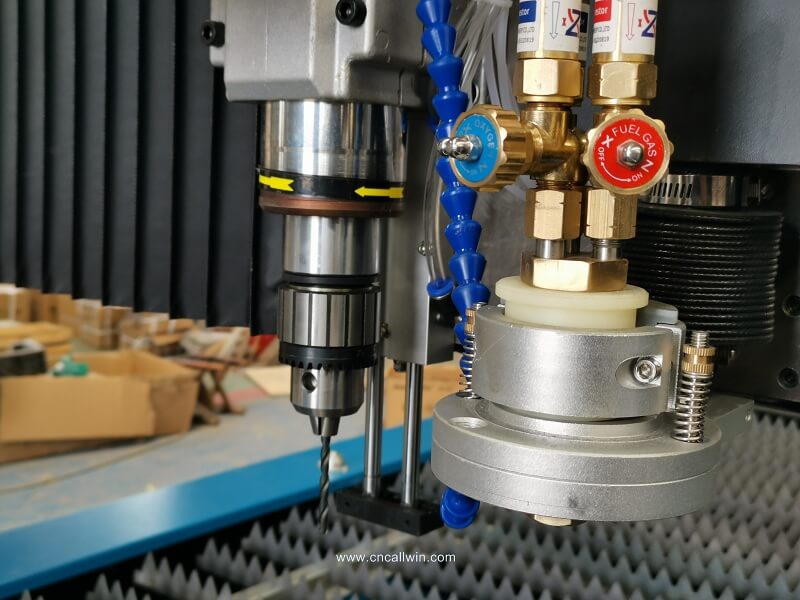

tapping smaller holes,marking pen and plasma cutting system is combined into CNC plasma cutting drilling machine

working stable and reliable, reasonable structure, good rigidity, powerful configuration function, with very high cost performance. Plasma cutting, flame cutting, drilling, tapping and marking can be combined on one set of CNC machinery

plasma cutting Drilling machine

| Model: | 1325/1530 |

| Category: | Plasma Cutter with Drilling Machine |

| Views: | 3500 |

| Brand: | allwin cnc |

| Rating: | 4.8 /5 based on 61 votes |

| Standard Price: | $3210.00 / Set |

| Price Range: | $2730.00 to $21000.00 / Set According to Configurations |

| Supply Ability: | 50 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| working area | customized |

parameter for cNC plasma cutting drilling machine with Flame(oxy-fuel gas)

| No. | Model 1530 | CNC plasma cutting drilling machine marking for option | |||

| 1 | X axis working area | 1500mm | |||

| 2 | Y Axis working area | 3000mm | |||

| 3 | Cutting Mode | Plasma+oxygen+Drilling head+marking pen | |||

| 4 | Driving motor | Panasonic servo | |||

| 6 | Controller system | FL2300 SHANGHAI FANGLING | |||

| 7 | Software | one set of Austraila FASTCAM | |||

| 8 | Plasma power | Hypertherm power or China brand | |||

| According to customer request | |||||

| 9 | cutting thickness for plasma | Depends on plasma source | |||

| 10 | Z travelling distance for drilling head | ≤120 mm | |||

| Z Rapid speed for drilling head | ≤ 120 mm / S | ||||

| ratation speed for drilling head | 50-1200n/min frequency control | ||||

| drilling size | Diameter ≤12 mm | ||||

| capacity for drilling | 2 – 30 mm | ||||

| position accuracy for drilling | ±0.15 | ||||

| 11 | Workbench | water table | |||

| 12 | display screen | LCD color screen with 4.7 inch size+Wireless handle wheel | |||

| 13 | Remote control | With | |||

| 14 | tramsmission method | USB | |||

| 15 | programe software | AutoCAD | |||

| 16 | Electrical components | CHINT | |||

| 18 | transmission for X,Y | X,Y axis Hiwin 2.0 Square guilld rails | |||

| Y axis high precision helical rack and pinion | |||||

| 19 | cutting table | Saw tooth mesa table and roll ball | |||

| 20 | Package size(L*W*H) | 3700MMX2250mmx1600mm | |||

| 21 | total weight for machine bed | 1850kgs | |||

| 22 | Machine color | customize according to customer request | |||

what is plasma cutting with drilling machine?

drilling and plasma cutting machine is designed to desktop structure,flexible lifting,quickly drilling and plasma cutting model.

it is controlled by NC program which supports steel drilling and cnc plasma cutting processing at same time.

plasma cutting with drilling machine helps to reduce time to loading or unloading metal sheet on table. so that improves working efficiency.

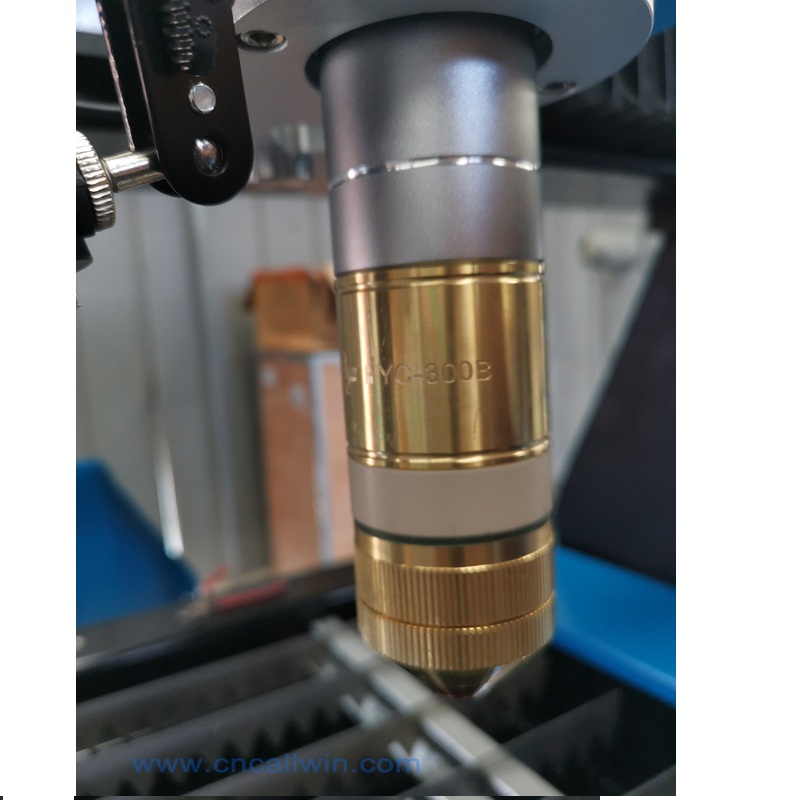

CNC Plasma drilling machine use servo control system

Servo motor Could monitor its drilling depth and drilling speed with stepless speed regulation.

The drilling diameter is from 1mm to 12mm and All drilling processing has water cooling system to following drilling head.

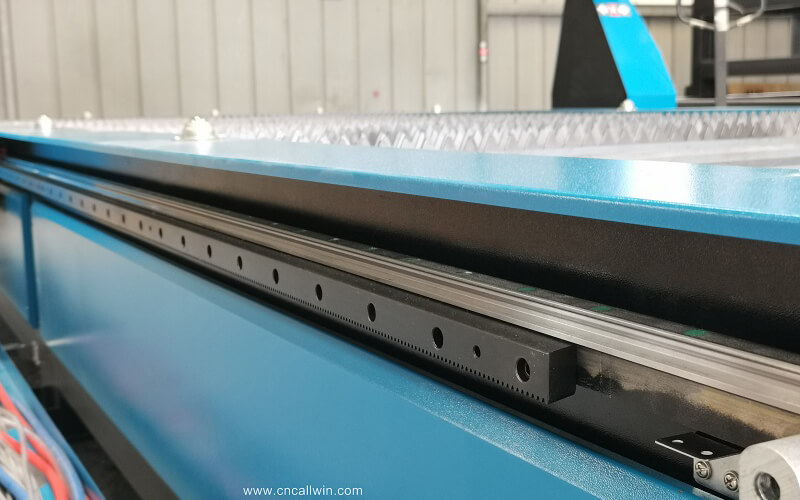

the whole machine designed with large cross section and steel structure beam with high precision guild rails with rack

Why more and more people prefer choose plasma cutter with drilling head??

Plasma cutting torch could drill diameter 14mm at minum.

However,some customers need drill smaller holes than 12mm on metal sheet then we have to add drilling head.

Drilling head to help plasma gun to drill to make plasma torch cut from its edge.

.edge cutting could prolong nozzles or electronics life.that is why as professional manufacturers for cnc plasma cutting machine we strongly advice end users try best to cut from edge not from central starts cutting.

CNC plasma cutting And Drilling integrated machine here we shortly called Plasma cutter with drilling machine

Characters for CNC plasma cutter with drilling machine

Allwin table plasma cutter with drilling machine is suitable for boiler manufacturing, power equipment, three-dimensional storage, shipbuilding enterprises, automobile manufacturing, steel structures and other metal processing industries.

how build up table style plasma cutting with drilling machine?

1.Standardized production, assembling parts are basically standard parts, reducing the failure rate,

for example: the machine bed, beam, column, sliding plate, drive plate and other precision related parts are all batched;

2. The bed is a heavy-duty bed, welded with a standard 10*200*3mm square tube, equipped with leveling feet.

3. The H-beam is 150*200*10mm strong square tube; and the guide rail surface and rack surface are both high-precision processing

4. The saw teeth is bent into a U shape by laser processing, which has good stability and high load-bearing strength; instead of an angle iron, thickness for saw teeth is 3mm;

5. The bed frame is an integrated design, and the cnc machinery color can be customized by the customers.

6. The standard configuration system can be replaced according to customer needs;

7. The drive is leadshine stepping drive; the failure rate is very low; it can also be replaced with a servo according to customer requirements

8. The lifter is a large lifting body 200mm, instead of a small portable lifting body with a stroke of 100;

9. The X axis has dust cover to protect the square guild rails with rail blocks.

10. Lubrication system to lubricate the slide block of the whole machine;

11. There are universal wheels one machinery table to make easier put metal sheet on machine bed.;

12. There is water table, which is convenient for customers to remove dust or smoke.

Other configurations are the same as the desktop plasma cutting machine. Compared with a desktop plasma cutting machine, it can easily perform drilling operations on the workpiece. The desktop CNC plasma cutting machine is suitable for metal cutting industries that require high precision such as shipbuilding, automobile manufacturing, and motorcycle manufacturing.

CNC Plasma Cutting And Drilling Integrated Machine Applications

USA Hypertherm/china huayuan power supply

China brand plasma power

| Power supply | Cutting thickness |

| 63A | 8mm |

| 100A | 15mm |

| 120A | 20mm |

| 160A | 30mm |

| 200A | 40mm |

Hypertherm brand plasma power

| Power supply | Cutting thickness |

| 45A | 8mm |

| 65A | 10mm |

| 85A | 12mm |

| 105A | 18mm |

| 125A | 25mm |

| 200A | 30mm |

package and delivery for Gantry cnc plasma cutter

All of our export machinery and equipment adopt standard plywood boxes after high temperature and high pressure treatment. The boxes meet the inspection standards of the United States and the European Union; the transportation method can be transported by plane, ship, or train according to customer requirements.

We have our own long-term cooperation transportation company, which will give us more favorable prices and feasible suggestions in transportation prices, which will minimize the customer’s freight expenses, and there will never be overcharges.

We also have Gantry CNC plasma cutting machine with rotary device to cut metal tubes for option.

International Shipping Around the World

All of our cutting machines can be sent to all parts of the world by sea, air, international expFEDEX, UPS, etc. You are welcome to feedback your needs and we can provide you with the most timely and accurate freight quotation, as well as the most timely and reliable service