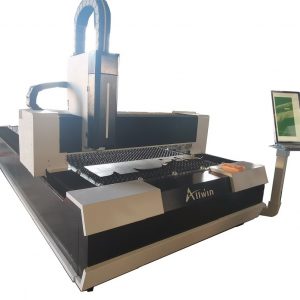

Mini Portable Fiber metal laser cutter

- Home

- Products

- fiber laser

- Mini Portable Fiber metal laser cutter

Mini portable fiber laser cutter adopts ipg laser source which has international advanced laser technology

IPG laser generator could cut brass aluminum..Everyone knows brass,aluminum is high reflective metal.

metal fiber laser cutting machine could works flexiblity.it could cut along with your design .

So if you are mold factory then you don’t need to open mold.

greatly saving new product development time, cutting speed, high precision.

Mini portable metal fiber laser cutter for advertising processing workshop is best choice.

mini portable fiber metal laser cutter is best option for jewelry works.

High speed with high accuracy,table perfance,best quality at very competitive price;

The workspace size can be customized to support different application scenarios. The following sizes of portable laser cutters can be customized: 90cm130cm, 150cm200cm, 200cm300cm, 300cm400cm, 300cm*600cm, etc.

Mini portable Fiber metal laser cutter 1000W IPG laser source Technical Parameter

Easy to learn and easy to operate,this can accurately control the operation of the cutting head to Maximize the utilization of materials and reduce tailling,

FSCUT 2000 and others optional could be change by clients’ advice

- High electro-optical conversion efficiency

- Customized output fiber length

- QBH connector

- Maintenance-free operation

- Wide modulation frequency range

- Small size, easy to install

- Fiber laser source use IPG laser,with better performance,ultra-long Lifetime for 100000hours

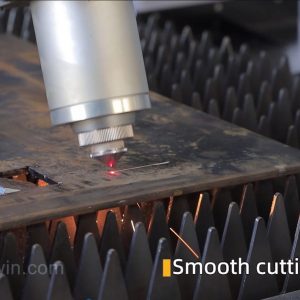

Our fiber laser machine install the Raytools cutting head with Automatic focssing

Fast perforation (especially the thick materials), The plate is not easy to heat, Does not affect the cutting head following

TBI guild rails with high precision coupling

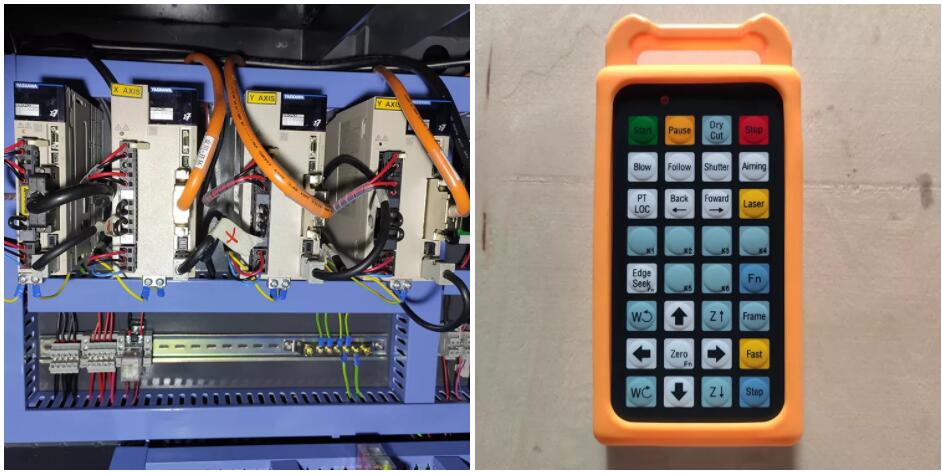

Top brand servo motor ,we coperate with Japan brand YASKAWA /FUJI and SHIMPO reducer,and you can choose according to the power you need;Remote control is easy to operate machne work.

specification for 9013 Mini portable fiber metal laser cutter

Parameter of Mini portable laser metal cutting machine

1 | Machine Name | 9013 fiber laser cutting machine |

2 | Laser machine cutting area | 1300x900mm |

3 | Laser type | Raycus brand ( Germany IPG for upgrade) |

4 | Laser power | 1500W fiber laser (3000W/2000W/1500W for upgrade) |

5 | Laser wave length | 1080nm |

6 | Control system | Cypcut controller with computer |

7 | Laser head | WSX laser cutting head |

8 | Transmission system | TBI Ball screw transmission |

9 | Driving system | Japan Panasonic servo motor |

10 | Electronic Components | French Schneider |

11 | Airtac pneumatic element | Japanese SMC |

12 | Max cutting speed | 35m/min |

13 | Cutting thickness | 0-25mm |

14 | Power requirement | 380V, 50/60Hz, 3PH |

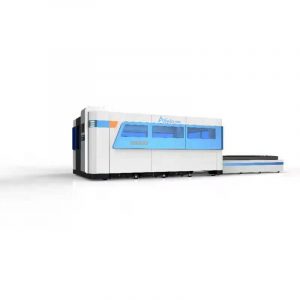

15 | Machine Sturcture | Full enclosed structure |

1.Ball screw transmission way, improve metal cutting precision.

2.Excellent Path Quality: Smaller laser dot and high work efficiency with high quality.

3. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

4. Stable Running: adopt top world fiber lasers generator, stable performance, key parts can reach 100,000 hours.

5. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

6. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

7. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

8. Easy Operations: fiber line transmission, no adjustment of optical path.

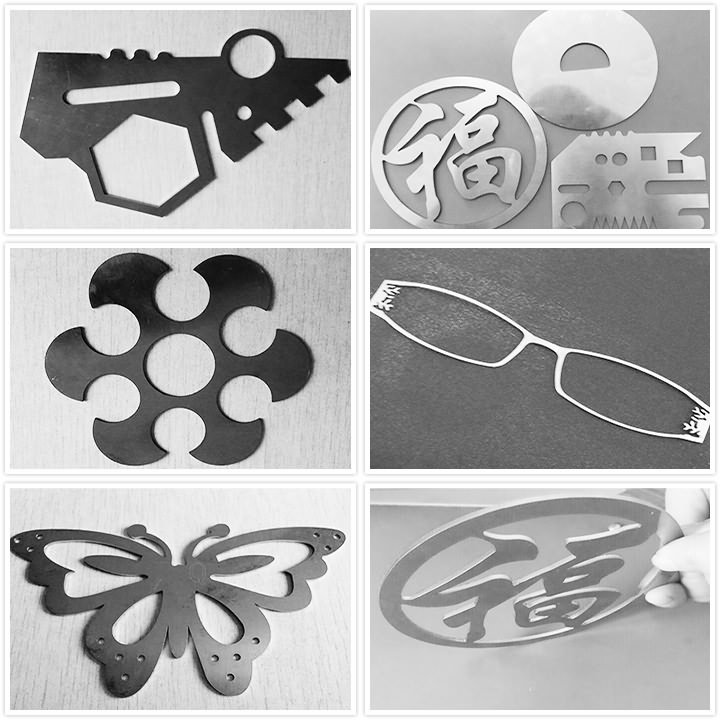

Application industries for metal Fiber laser cutting machine

Industries metal fiber laser cutting machine is suitable for cutting all kinds of metals.Stainless steel, steel,iron,brass,copper,Aluminum, aluminum alloy,titanimum,carbon steel

its cutting effect is best for metal materials compared to other metal cutting machines because of fiber laser cutting machine are not easily oxidized with very fast cutting speed

CNC fiber laser cutting machine is very popular in Aerospace manufacturing,precision indstries parts manufacturing,shipbuilding manufacturing,subway accessories,electronical appliances,elevator industries.metal fabrication and other smaller business industries,like Gold,silver, jewelry and ornaments.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional metal industrial fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.