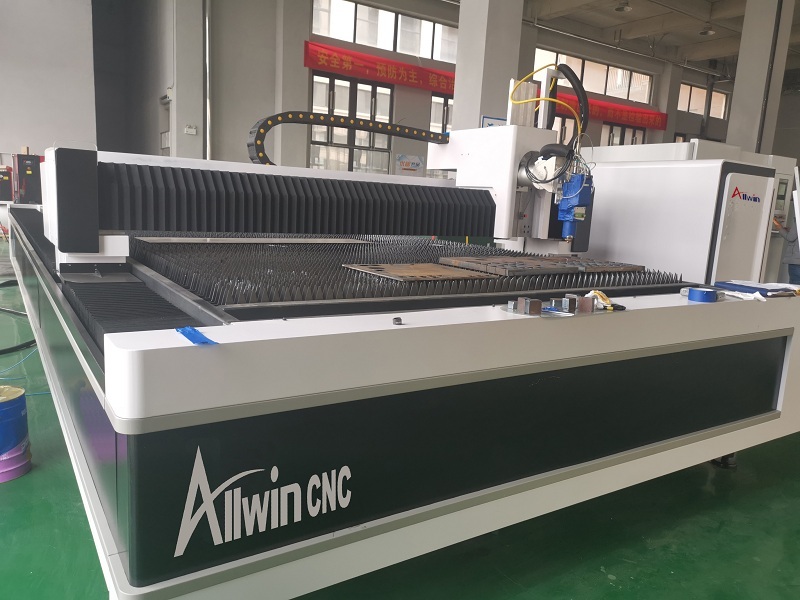

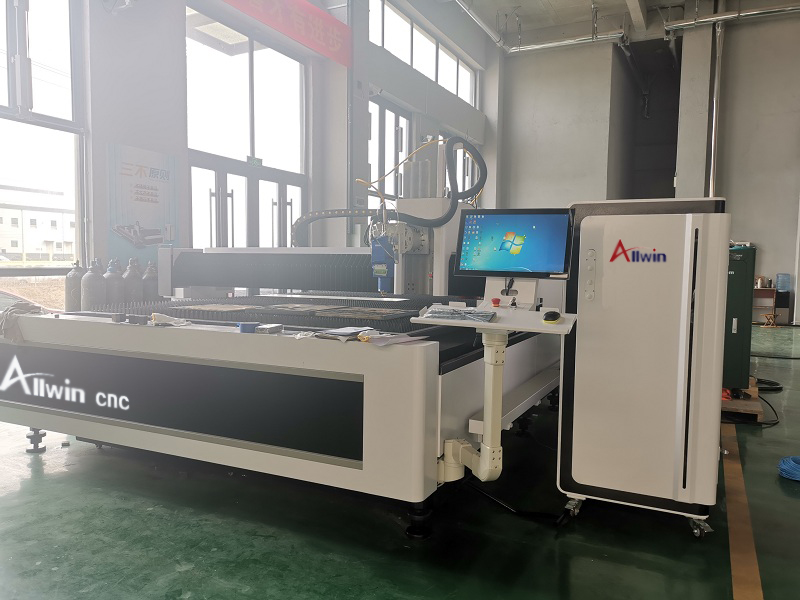

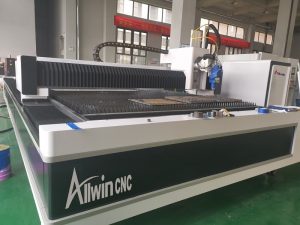

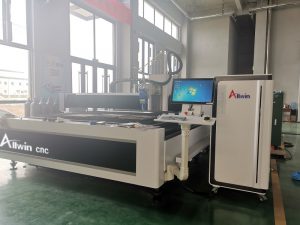

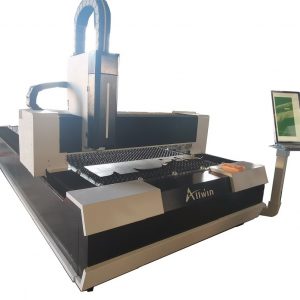

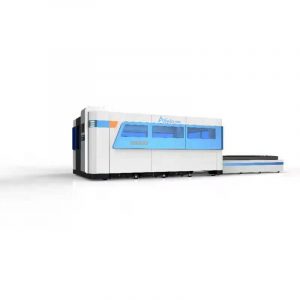

5 axis bevel laser cutting machine

- Home

- Products

- fiber laser

- 5 axis bevel laser cutting machine

5 axis bevel laser cutting machine features

The 5 axis bevel laser cutting machine could rotate along with the A and B axis.its best option for bevel- cuts

Automatic adjustment of cutting Angle, automatic completion of cutting track, more intelligent and convenient. The rotating angle for laser head is 360 degree so that It could cuts metal at bevelling frame over 45degree(±45°)

| Model: | 3015/4020/6020/8020 |

| Category: | 5 AXIS BEVEL LASER CUTTING MACHINE |

| Laser Source | Raycus 6000W OR 12000W for option |

| brand | allwin cnc |

| Cutting mode | 5 AXIS with Bevel-cuts |

| Standard Price: | $USD 125000.00 / Set |

| working area | customized according to demand |

| table bed | Heavy with high-temperature rocessing |

| Payment Terms: | T/T,L/C |

5 axis bevel laser cutting machine Technical Parameters Model

| machine model: | 3015/4020/6020/8020 |

| max working area | 1500mmx3000mm/2000mmx4000mm/2000mmx6000mm/2000mmx8000mm |

| Cutting angle | ±45° |

| Laser source | 6000W/12000W RAYCUS fiber laser |

| laser head | Swiss RAYTOOLS with auto focus |

| software | Professional 5 axis bevelling cuts controlling system with Cypcut software |

| motor and driver | Japanese YASKAWA servo motors 1300W |

| Reducer | Japan SHIMPO reducer |

| Water chiller | S&A brand with Dual temperature,dual control |

| Rack and pinion | Taiwan brand T-WIN rack and pinion |

| Guild rails | HIWIN GUILDER RAIL |

| Exhaust fan | Blower Exhaust fan |

| motor and driver | Japanese YASKAWA servo motors 1300W |

| Voltage stablizer | YES |

| X,Y axis repated postition accuracy | ±0.1/10000mm |

| Accessories included | 1 SET RAYCUS FIBER LASER SOURCE 2000W |

| 1 SET RAYTOOLS LASER HEAD(AUTOMATIC FOCUS) | |

| 1 SET WATER CHILLER | |

| CYPCUT SOFTWARE | |

| INDUSTRIAL COMPUTER | |

| FAN | |

| LASER PROTECTION GLASSES | |

| FIBER LASER CUTTING BED |

how choose 5 axis Bevel laser cutting machine

What working size do you need?

support customize working size for laser cutting bed size according to metal material size.

regular effective working area for fiber laser cutting machine is 3000mm*1500mm/3000mm*8000mm/6000mm*1500mm

What brand of fiber laser generator?

in order to achieve Revenue output maximization.

Raycus,Max or IPG brands are most welcome in china.

What power of 5 Axis bevel laser cutting machine?

6000W OR 12000W OR 20000W is more popular.

What power of fiber laser source is most important factor to decide how much is this machine?

conclude:you need check up how much money in your pocket?is It necessary for your work?

after all 5 axis bevel laser cutting machine is expensive machine.

How does the fiber laser cutting machine work?

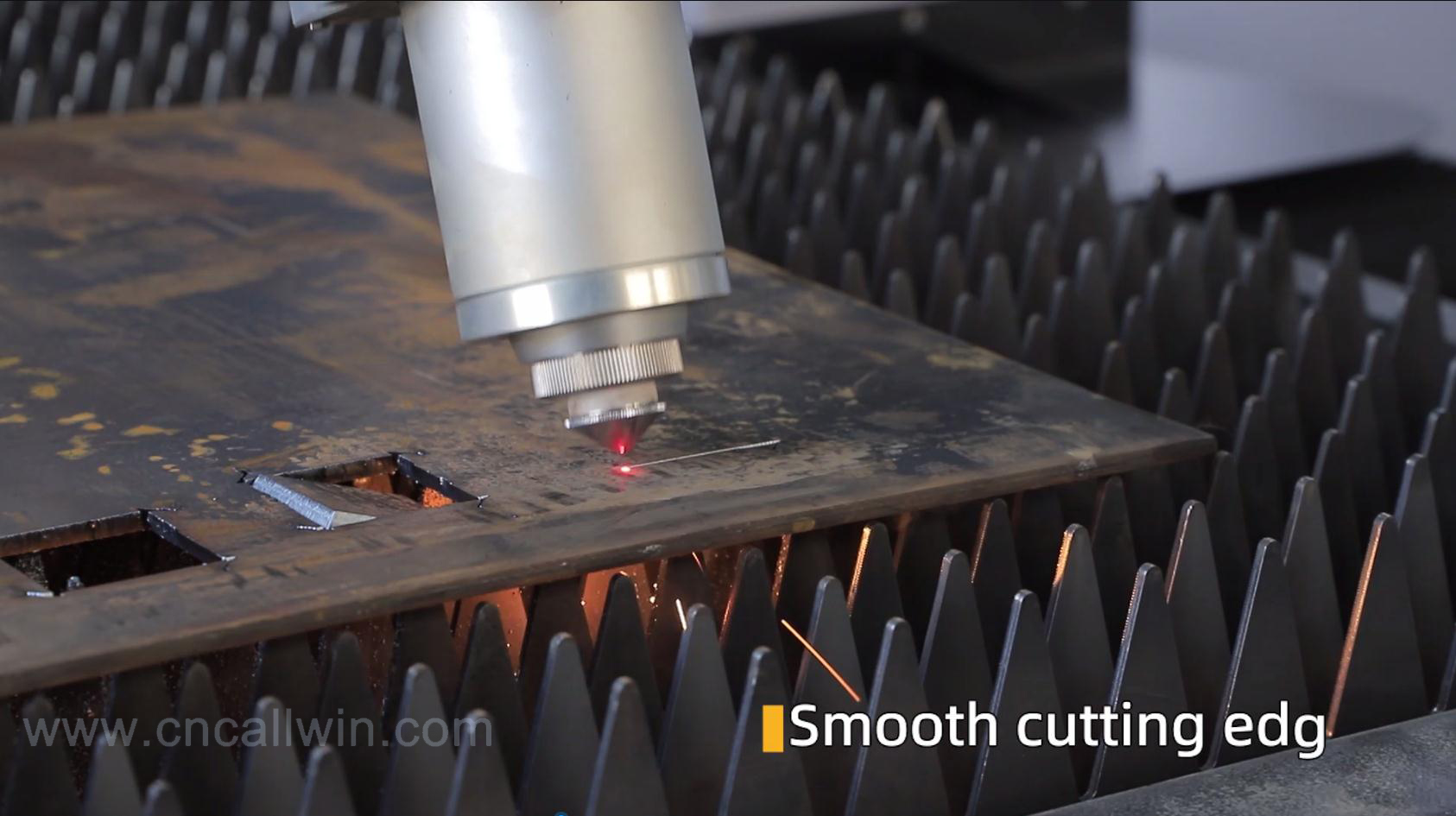

Metal fiber laser is a new type of laser that is newly developed in the world. This laser cnc outputs high-energy-density laser beam, which is concentrated on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the numerical control mechanical system. Realize automatic cutting by irradiating position, fast speed and high precision.

why choose 5 axis bevel laser cutting machine?

Many metal sheet parts need to be welded together after cutting during the metal sheet making processing.

However,The Vertical section is difficult to weld together.

We have to make incision to be bevel shaped because of Bevel cut could weld strong..

The Bevel cutting technology developed by ALLWIN laser can directly cut bevel of different angle +-45 degree.

5 axis bevel laser cutting machine help us to save labor cost and improve cutting efficiency.

Compared to traditional vertical cutting method Especially to special requirements.

the Ultra-high power bevel laser cutting machine can fnish once without secondary cutting and grinding

so working efficiency is improved by 75%.

Bevel surface is much cleaner.

bevelling groove surface is much cleaner than traditional arc bevelling processing.

clean or smooth incision can be welding together directly without secondary grinding.

stable cutting processing for large quantities

using High power bevel laser cutting machine could cut at small quantities.

Testing cutting samples at small Quantities then make mass-production

Widely application for Thick plate cutting.

5 Axis Bevel laser cutting machine with high power and compatible with more thickness of the plate.

6000W/12000W 5 Axis bevel laser cutting machine could easy cut 20mm thick plate.

5 axis bevel laser cutting machine is widely used in boiler,pressure vessel,nuclear power,thermal power industries.

V bevelling cuts/A bevelling cuts/K bevelling cuts/Y bevelling cuts/X bevelling cuts/

Improved processing efficiency.

cutting samples for 5 Axis bevel laser cutting machine

ALLWIN CNC Fiber Laser Cutting Machine Warranty.

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

How Much Is 5 axis bevel laser cutter?

The procurement cost of 5 Axis laser cutter consists of items:

1. Laser cutter spare parts. laser nozzles,protection lens or focus lens.

2. Laser cutter software

3.Fiber laser source 6000W/12000W+fiber laser head+water chiller+A.B rotated axis.

4. lathe bed:heavy duty lathe bed with high-temperature processing.

5. Shipping cost.

6. Customs.

A fiber laser cutter cost is from 80,000$usd to 150,000.00$usd.depends on laser generator

Package for CNC Laser Machine from ALLWIN CNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard pratective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional metal industrial fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.