CNC Cutting Spare Parts China Supply

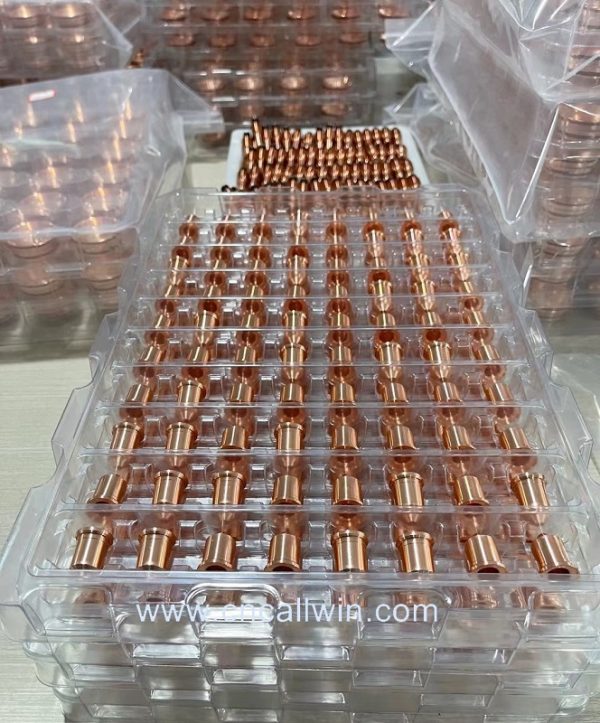

The plasma cutting machine includes lots of plasma cutter consumable parts

we focus on supplying plasma electrode, plasma nozzle, plasma Retainning cap, plasma swirl ring,plasma shiled cap, Cutting torch, cutting torch assembly at super competitive price

CNC Plasma Cutting torch/gun spare parts/consumables

What Are Plasma Cutter Consumables?

The plasma arc is created by using high frequencies, Pilot arc is first created between the electrode and the nozzle.

what brand of plasma cutting consumables can we provide?

Hypertherm,kaliburn(lincln),kjellberg

Hypertherm, Thermadyne, Kaliburn, kjellberg and Esab brand.

The electrode is a narrow piece of copper containing hafnium ,its job is to receive electrical current from inside of plasma torch.The nozzle focuses the plasma arc and the gas that surrounds it to make a clean and precise cut.Retainning cap is hold all plasma accessories together.

The plasma consumables we provide includes different brand of plasma generator.

Consumables suitable for p80 plasma torch include electrodes, nozzles 1.1, 1.2, 1.3, 1.4, 1.5, 1.6.

Consumables for Hypertherm series plasma cutting machines, including nozzle, electrode, shield cap, retaining cap, swirl ring.

Consumables for Lincoln kaliburn series plasma cutting machine, including nozzle, electrode, shield cap, retaining cap, swirl ring.

The plasma consumables we provide are original, OEM, and substitutes.

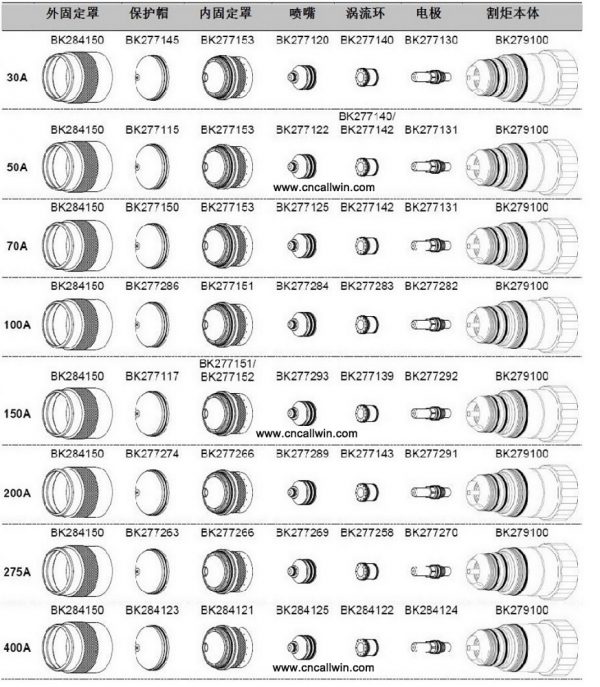

LINCOLN/KALIBURN BRAND spare parts/consumable nozzles/electrodes/shield cap/retainning cap/swrl rings

LINCOLN INNER RETAINING CAP 277151/277266/277153

277151 for 100A/277266 for 200A-275A

277153 for 50A-70A

LINCOLN electrodes 277131/277282/277292/277291/277270 for 50A-275A KALIBURN plasma source

NOZZLES for LINCLN/KALIBURN plasma generator includes:277122 for 50A 277125 for 70A; 277284 for 100A; 277293 for 150A and 277289 for 200A 277269 for 275A

sHIELD CAP(Retaining cap) for LINCLN/KALIBURN plasma generator includes:277153 for 50A-70A; 277151 for 100A;277266 for 200A-275A

KJELLBERG BRAND plasma consumables(Nozzles/electrodes/retaining cap/swirl gas gap)

Cathode(Electrode)F012, Nozzles F2007 cutting nozzles F2010 for 55/90A

Nozzles cap F3004.

Swirl gas(Sheild cap)F4120 for 30A plasma source

Swirl gas cap(Shield cap):F4120 for 35A/55A-60A.

Swirl gas cap F4030 is for 90-200A.

How to order accessories for CNC plasma cutting machine.

Any machines has its own maintaince cost for their plasma accessories/consumables

of course CNC plasma cutting machine has its their own accessories.

Here let us explain something about consumbles or accessories spare parts on CNC plasma cutting machine.

Different brand plasma generator has its own accessories nozzles or electrodes or protection caps..

nozzles and electrodes are most largest needed compared to other plasma cutter consumables.

Here we are listing some models which sales amount is bigger.

1. P80 nozzles and electrodes

They are used for black wolf torch with air cooled plasma generator 65A,100A,130A

P80 plasma gun are purchased by users because of lower price for accessories Nozzles or electrodes

plus their usage life is fine.

Nozzles holes for P80 torch is 1.1mm 1.3mm 1.5mm 1.7mm..

China brand plasma nozzles and electrodes P80

Guide you order plasma cutter accessories/consumables.

If your Plasma torch is Air cooled for China brand 60A/100A/120A/

and you want your lasma consuambles works long time.

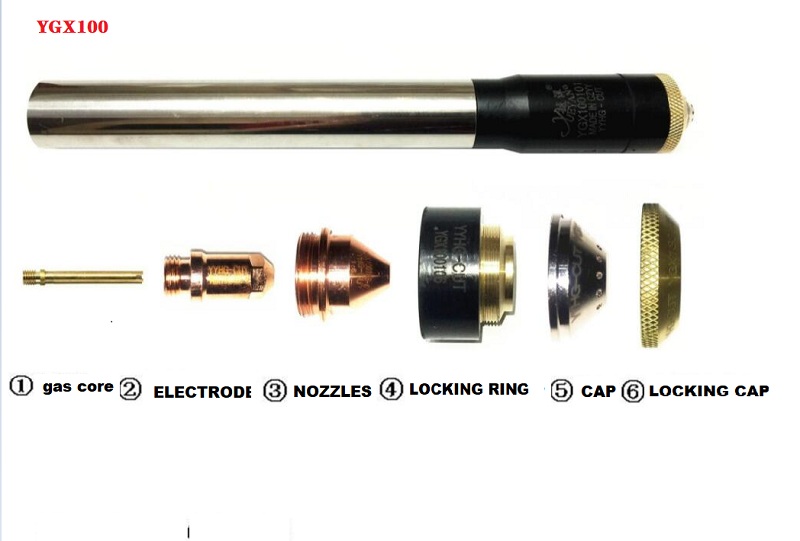

than We strong suggest you another mode Fine plasma torch air cooled with accessories–YGX100 torch

YGX100 Torch is for 63A,100A,120A,130A air cooled plasma source.

Nozzles or electrodes for YGX100 torch have clean cuts with longer life and less slag.

Compared to P80 consumbles or accessories. Its price is higher 10% than P80 accessories.with the higher request for CNC plasma works,more and more users chasing on high quality clean result.YGX100 plasma torch became famous.

Reference following table to choose what diameter of tips or nozzles.

VIEW MORE PARAMETER CLICK HERE

| metal thickness(mm) | nozzles size(mm) | current(Amper) |

| 1mm-3mm | 1.1 | 63A |

| 3mm-5mm | 1.3 | 100A |

| 5mm-8mm | 1.5 | 120A |

| 8mm-14mm | 1.7 | 120A |

Water Cooled Plasma Torch

YH-300 water cooled plasma torch is for water cooled plasma generator 160A,200A,300A,400A-

Please check following chart for its details for Nozzles or Electrodes for YH-300 fine plasma gun.

View more info for advice choosing right accessories according to different thickness of metal.

| plasma cutter Accessories for YH-300B torch | |

| Electrodes | YH02201 |

| Nozzles 1.3mm | YH02413 |

| nozzles 1.5mm | YH02415 |

| nozzles 1.7mm | YH02417 |

| nozzles 1.9mm | YH02419 |

| nozzles 2.1mm | YH02421 |

| nozzles 2.3mm | YH02423 |

| nozzles 2.5mm | YH02425 |

| nozzles 2.8mm | YH02428 |

| Protect Cap | YH02701 |

Hypertherm plasma cutter consumbales/accessories

The Hypertherm Powermax 45XP/65/85/105 Electrode #220842 and nozzles#220941 is what you need to keep productive,every time arc come out than electrodes or nozzles will get damaged

Electrodes#220842 and nozzles#220941 is professional designed for Hypertherm power max plasma generator.power max 45A,power max 65A and powermax 85 Power max 105 plasma cutters

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220671 | powermax45 |

| 2 | shield cap | 220673 | |

| 3 | nozzle retaining cap | 220713 | |

| 4 | electrode | 220669 | |

| 5 | swirl ring | 220670 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220671 | powermax45(handheld) |

| 2 | shield cap | 220674 | |

| 3 | nozzle retaining cap | 220713 | |

| 4 | electrode | 220669 | |

| 5 | swirl ring | 220670 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220941 | powermax45xp |

| 2 | shield cap | 220817 | |

| 3 | outer retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220941 | powermax45xp(handheld) |

| 2 | shield cap | 220818 | |

| 3 | outer retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220819 | powermax65 |

| 2 | shield cap | 220817 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220819 | powermax65(handheld) |

| 2 | shield cap | 220818 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220816 | powermax85 |

| 2 | shield cap | 220817 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220816 | powermax85(handheld) |

| 2 | shield cap | 220818 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220857 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220990 | powermax105 |

| 2 | shield cap | 220993 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220994 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220990 | powermax105(handheld) |

| 2 | shield cap | 220992 | |

| 3 | nozzle retaining cap | 220854 | |

| 4 | electrode | 220842 | |

| 5 | swirl ring | 220994 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220975 | powermax125 |

| 2 | shield cap | 220976 | |

| 3 | nozzle retaining cap | 220977 | |

| 4 | electrode | 220971 | |

| 5 | swirl ring | 220997 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 220975 | powermax125(handheld) |

| 2 | shield cap | 420000 | |

| 3 | nozzle retaining cap | 220977 | |

| 4 | electrode | 220971 | |

| 5 | swirl ring | 220997 | |

| NO. | NAME | Part NO. | MODEL |

| 1 | nozzle | 420044 | Maxpro200 |

| 2 | shield cap | 420045 | |

| 3 | nozzle retaining cap | 220936 | |

| 4 | electrode | 220937 | |

| 5 | swirl ring | 220488 |

Licoln kaliburn plasma cutter Nozzle electrodes consumbales/accessories

Kaliburn Plasma Consumables,Nozzle,Electrode,Swirl ring,shield cap,Retaining cap

Jinan allwin cnc machinery is an important supplier of plasma consumables, our company can produce or sell plasma torch accessories including kaliburn nozzle, kaliburn electrodes, kaliburn shield cap, kaliburn retaining cap, kaliburn swirl ring; These consumables can be used for cutting Stainless steel, carbon steel, copper, aluminum and other metals.

Our Lincoln Karliburn spare parts have a long service life. These Lincoln plasma consumables we produce use high-quality materials and high-standard processes to ensure reliable product quality.Our Karlibunr consumables have reached the quality standard of the original product OEM;

Our plasma consumables are cheap and have a long service life, and will reduce a lot of costs for customers who use them in large quantities; our consumables are of reliable quality, and the surface of the processed workpiece is smooth and tidy, free of residue and high verticality.

Kaliburn Plasma Consumables &spare parts

| NO. | RefNO. | COSME | Description |

| 1 | *BK277154 | COS277154 | Outer-Retaining Cap, Mild Carbon Steel/Stainless Steel, 30A-275A |

| *BK284150 | COS284150 | Outer-Retaining Cap, Mild Carbon Steel/Stainless Steel, 30A-400A | |

| 2 | BK277145 | COS277145 | Shield Cap, Mild Carbon Steel, 30A |

| BK277115 | COS277115 | Shield Cap, Mild Carbon Steel, 50A | |

| BK277150 | COS277150 | Shield Cap, Mild Carbon Steel/Stainless Steel, 70A | |

| BK277286 | COS277286 | Shield Cap, Mild Carbon Steel, 100A | |

| BK277117 | COS277117 | Shield Cap, Mild Carbon Steel, 150A | |

| BK277274 | COS277274 | Shield Cap, Mild Carbon Steel/Stainless Steel, 200A | |

| BK277263 | COS277263 | Shield Cap, Mild Carbon Steel, 275A | |

| BK284123 | COS284123 | Shied Cap, Mild Carbon Steel, 400A | |

| BK277146 | COS277146 | Shield Cap, Stainless Steel, 100A | |

| BK277298 | COS277298 | Shield Cap, Stainless Steel, 150A | |

| BK277211 | COS277211 | Shied Cap, Stainless Steel, 260A | |

| BK284115 | COS284115 | Shield Cap, Stainless Steel, 400A | |

| 3 | BK277153 | COS277153 | Nozzle Retaining Cap, Mild Carbon Steel, 30A-70A |

| *BK277151 | COS277151 | Nozzle Retaining Cap, Mild Carbon Steel, 100A-150A | |

| *BK277152 | COS277152 | Nozzle Retaining Cap, Mild Carbon Steel, 150A | |

| *BK277266 | COS277266 | Retaining Cap, Mild Carbon Steel, 200A-275A, Stainless Steel, 150A-200A | |

| *BK284121 | COS284121 | Nozzle Retaining Cap, Stainless Steel, 400A | |

| *BK277113 | COS277113 | Nozzle Retaining Cap, Stainless Steel, 70A-100A | |

| *BK277280 | COS277280 | Nozzle Retaining Cap, Stainless Steel, 260A | |

| *BK284156 | COS284156 | Nozze Retaining Cap, Stainless Steel, 400A | |

| 4 | BK277120 | COS277120 | Nozzle, Mild Carbon Steel, 30A |

| BK277122 | COS277122 | Nozzle, Mild Carbon Steel, 50A | |

| BK277125 | COS277125 | Nozzle, Mild Carbon Steel, 70A | |

| BK277284 | COS277284 | Nozzle, Mild Carbon Steel, 100A | |

| BK277293 | COS277293 | Nozzle, Mild Carbon Steel, 150A | |

| BK277289 | COS277289 | Nozzle, Mild CarbonS tee, 200A | |

| BK277269 | COS277269 | Nozzle, Mild Carbon Steel, 275A | |

| BK284125 | COS284125 | Nozzle, Mild Carbon Steel, 400A | |

| BK277124 | COS277124 | Nozzle, Stainless Steel, 70A | |

| BK277126 | COS277126 | Nozzle, Stainless Steel, 100A | |

| BK277297 | COS277297 | Nozzle, Stainless Steel, 150A | |

| BK277287 | COS277287 | Nozze, Stainless Steel, 200A | |

| BK277118 | COS277118 | Nozzle, Stainless Steel, 275A | |

| BK284157 | COS284157 | Nozzle, Stainless Steel, 400A | |

| 5 | BK277140 | COS277140 | Swirl Ring, Mild Carbon Steel, 30A-50A, Stainless Steel, 70A |

| BK277142 | COS277142 | Swirl Ring, Mild Carbon Steel, 50A-70A | |

| BK277283 | COS277283 | Swirl Ring, Mild Carbon Steel, 100A | |

| BK277139 | COS277139 | Swirl Ring, Mild Carbon Steel, 150A, Stainless Steel, 150A/260A | |

| *BK277143 | COS277143 | Swirl Ring, Mild Carbon Steel, 200A | |

| *BK277258 | COS277258 | Swirl Ring, Mild Carbon Steel, 275A | |

| *BK279422 | COS279422 | Swirl Ring, Mild Carbon Steel, 400A | |

| *BK277141 | COS27741 | Ring, Stainless Steel, 100A | |

| *BK277259 | COS277259 | Swirl Ring, Stainless Steel, 200A | |

| *BK284122 | COS284122 | Swirl Ring, Stainless Steel, 400A | |

| 6 | BK277130 | COS277130 | Electrode, Mild Carbon Steel, 30A |

| BK277131 | COS277131 | Electrode, Mild Carbon Steel, 50A-70A | |

| BK277282 | COS277282 | Electrode, Mild Carbon Steel, 100A | |

| BK277292 | COS277292 | Electrode, Mild Carbon Steel, 150A | |

| BK277291 | COS277291 | Electrode, Mild Carbon Steel, 200A | |

| BK277270 | COS277270 | Electrode, Mild Carbon Steel, 275A | |

| BK284124 | COS284124 | Electrode, Mild Carbon Steel, 400A | |

| BK277132 | COS277132 | Electrode, Stainless Steel, 70A | |

| BK277133 | COS277133 | Electrode, Stainless Steel, 100A | |

| BK277135 | COS277135 | Electrode, Stainless Steel, 150A-260A | |

| BK284159 | COS284159 | Electrode, Stainless Steel, 400A |

How to find right plasma cutter consumables?

We have been receving complaints from customers..We don’t like the torch we are using can we change to lower-frenquence torch?or can we change to the style troch we want??Here some tips for your reference.

What brand of your old plasma generator?

Different brand for plasma source has its own plasma accessories.

What thickness of your metal plate?

we can suggest you what size for Nozzles holes.

the most easy way is check model number on plasma cutter accessories and tell your supplier what you want.

do you know when to replace plasma cutting accessories?

How do you know when to replace nozzles electrodes on plasma cutter torch?

1)checking ARC light

The life of the electrodes or nozzles can be seen from the Arc light. In general,the arc light is blue means that electrode will be exhausted soon,we need replace it.

2)checking verticality(plane surface)

checking verticality(plane surface)of the cut plate plasma arc direction..if its verticality or plane surface is very bad than need check plsma nozzles or electrodes.

3)checking Kerf

Cutting kerf or slot becomes uneven furthermore,plasma cutting machine can not cut through metal sheet completely as same as before which indicates need replace nozzles broken.

4)New nozzles connect very tight with electrodes.

Sometimes the plasma new nozzles or electrodes can not catch arc light.because the plasma cutter nozzles you bought is not right size.so that caused the internal and External electrodes are short-circuited.we need loose half circle it will work well.

Generally speaking,Hypertherm plasma cutter has alarm code,the system could automatically monitor the life of electrodes or nozzles.

How to Extend life of plasma cutter nozzles or electrodes?

1)Trying best to avoid piercing cuts;we should start arc at edge not center piercing

Piercing or perforation will make strong arc light or water hurt the nozzles.

Piercing or perforation is the most important reason to damage nozzles or electrodes.that is why more and more users like to add drilling head.use drilling head to pre-drilling a whole than plasma torch start cutting from the drilling holes.

correct work procesing is make plasma tips directed at edge then start Arc

2)trying to cut within range of the rated cutting thickness

Plasma source has its own limit of cutting capacity

Don’t make plasma source to work at its limit of their capacity.

Here we list cutting capacity of plasma cutter source for your reference.

| LGK-100IGBT | LGK-120IGBT | LGK-160 IGBT | LGK-200 IGBT | LGK-300 IGTB | LGK-400A | |

| Current adjust range | 30~100A | 30~120A | 40~160A | 40~200A | 40-300A | 50-400A | |

| Quality cutting thickness (Carbon Steel) | 0.3~13mm | 0.3~15mm | 1~20mm | 1~30mm | 1-45mm | 1-60mm | |

| Max. cutting thickness (Carbon Steel) | 22mm | 25mm | 35mm | 55mm | 70mm | 90mm | |

| Plasma gas | Compressed air | ||||||

| The working plasma gas pressure | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.45~0.6MPa | 0.5-0.6MPA | 0.55-0.6Mpa | |

| Torch cooling mode | Air cooling | Air cooling | Water cooling | Water cooling | Water cooling | water cooling | |

| Arc striking mode | Non-contact | ||||||

3)keep proper distance from plasma cutter tips to metal sheet

in genera,its distance is 3-8mm.

too far from plasma nozzles to metal sheet,it will reduce piercing capacity of pilot arc piercing also making electricity power waste;Too close between plasma tips and metal sheet.it will damage plasma accessories quickly.

4)Reduce unnecessary Arc-starting or Arc-lead

Arc-starting moment will damage devasted to plasma consumables like Nozzles or electrodes

Before starting cutting, we should use “simuation”function to make torch moves within working area to avoid Arc-starting.

5)Avoid slag from upper or bottom–try best to keep clean cuts.

we should give clean environment when replace them,any dirty things will effect plasma cutting system and block its

gas circuit.

6)suplying clean and dry compressed air

Wet or dirty compressed air could make plasma cutter consumables get wet after some times it will get rusty.

not clean air supplying to plasma source could block gas circuit on plasma torch which caused low air supplying to nozzles or electrodes.which pilot ARC gather into nozzles.This is very possiblity to damage consumables wear.

7)connecting good work cable

We must provide enough rated input capacity according to plasma generator’s requsted.different plasma power request different size for cable.Poor cable works always are causing arc starts. Generally speaking,

100A plasma source needs be sure to sectional area ≥6(mm2) 200A plasma source needs sectional area ≥16(mm2)300A plasma source needs ≥35mm2

must be sure to follow setting chart in manual books using right consumables.we hope our experience could help you to save some cost.if you need any help please contact with us.

we hope you could know how to extend life of plasma cutter consumables/accessories after read this articles.

How To Choose CNC Plasma Cutting Torch Electrodes And Nozzles

How to choose CNC plasma cutting machine electrodes and nozzles? Due to its low cost, high cutting efficiency, and good cutting effect, plasma cutting machines are widely used in the field of metal cutting.

In the plasma cutting process, the consumables include plasma nozzles(hypertherm nozzle,kaliburn nozzle,p80 nozzle),plasma electrodes(hypertherm electrodes,kaliburn electrodes,p80 electrodes), plasma shield cap(hypertherm shield cap,kaliburn shield cap),plasma swirl ring(hyperthermswirl ring,kaliburn swirl ring) plasma nozzle retaining cap, and outer retaining caps. Among them, the consumables with the largest consumption and the highest occupation cost are the plasma nozzles and electrodes. There are many kinds of plasma cutting power sources on the market now, such as Hypertherm, Lincoln kaliburn, Huayuan, Huarong, etc. No matter what kind of plasma cutting machine needs to use nozzles and electrodes, so in the process of daily use, nozzles and electrodes occupy a lot of large cost of use.

we would like to share some information to help you to extend their life.

The factors that affect the service life of the wearing parts of the plasma cutting machine are as follows:

- Improper operation of plasma cutting: For example, the cutting nozzle is too close to the steel plate during cutting (the size of the cutting nozzle from the steel plate during plasma cutting is generally not less than 3~8 mm) the external input voltage is too high or unstable, etc.

- The consumables do not match the model of the torch: the electrode nozzle does not match the torch the size, specification, and model of the electrode nozzle are inconsistent with the original torch resulting in a mismatch. Although the appearance size looks similar, there may be slight differences in the size of different manufacturers.compared to the original cutting torch of the electrode nozzle,they may not be able to work well so it is easy to reduce the service life of consumable parts.

- Quality problems: If the quality of the electrode nozzle is unqualified, this is very important.

- cutting material :such as different materials like stainless steel or carbon steel or copper or aluminum.Although correct operation method,If you cuts ordinary steel plate or stainless steel life for plasma cutter consumables are longer than cutting on Copper,aluminum metal thickness and cutting process arrangement of the cutting workpiece will also affectlife of consumable parts.

- Factors such as cutting process, material and thickness of workpiece, can affect the service life of plasma nozzle and plasma electrode.During the cutting process of the plasma cutting machine, the electrode nozzles consumed by ordinary carbon steel plate, stainless steel, cast iron and other workpiece materials are relatively small, but the consumption of copper and aluminum plates is relatively large.

- In terms of cutting thickness, cutting the plate below 10mm saves the cutting nozzle, and the plate above 16mm consumes the cutting nozzle. In terms of cutting process, perforation cutting consumes more than twice as much nozzle as edge arc cutting.

Therefore, when choosing the plasma power supply and cutting nozzle, it is necessary to select the plasma power supply with the appropriate power and the nozzle electrode with the matching current size and caliber size, so as to achieve the best cutting effect and service life.

We hope our advice could help you.if you have any purchase plan than contact with us.