maintenance for metal fiber laser cutting machine.

Provide proper maintenance is very necessary to make equipment work stable and prolong life.

How to Maintain fiber laser cutter?what parts is the most important to give them maintenance?

Due to Fiber laser equipment is assembly with different components(mainly parts are Servo motor,water cooler,Laser source)

Correctly boot sequence

Main switch—–Servo motor—-water cooler——laser source——turn on computer

Correctly shutdown sequence

turn off Servo motor—-turn off software—-turn off computer—switch off laser source—switch off water cooler—-Main switch

1) maintenance for Fiber laser source:

Fiber laser source is the most important compeonents for one set fiber laser cutting machine

Environmental requirements for fiber laser source

The humidity of laser working environment: 10%-80%;

1) must turn on water chiler 20-30 minutes untill water temperature 20℃-30℃ and then turn on fiber laser source.

Generally speaking, lower than 30℃ in summer,higher than 20℃ in winter

2)Prevent dew in summer.

In hot summer,air conditioner or high-power cooling fan should be installed beside the chiller and fiber laser source.

Give fiber laser source a comfortable constant temperature.

In case,you find Dew on the laser head in the morning. need firstly turn on laser source to remove dew than make machine start to cut.

3)Add Antifreeze in winter.

When the lowest temperature reaches 3 ~ 5 ℃, Add antifreeze in winter ( 1/3 antifreeze + 2/3 pure water)

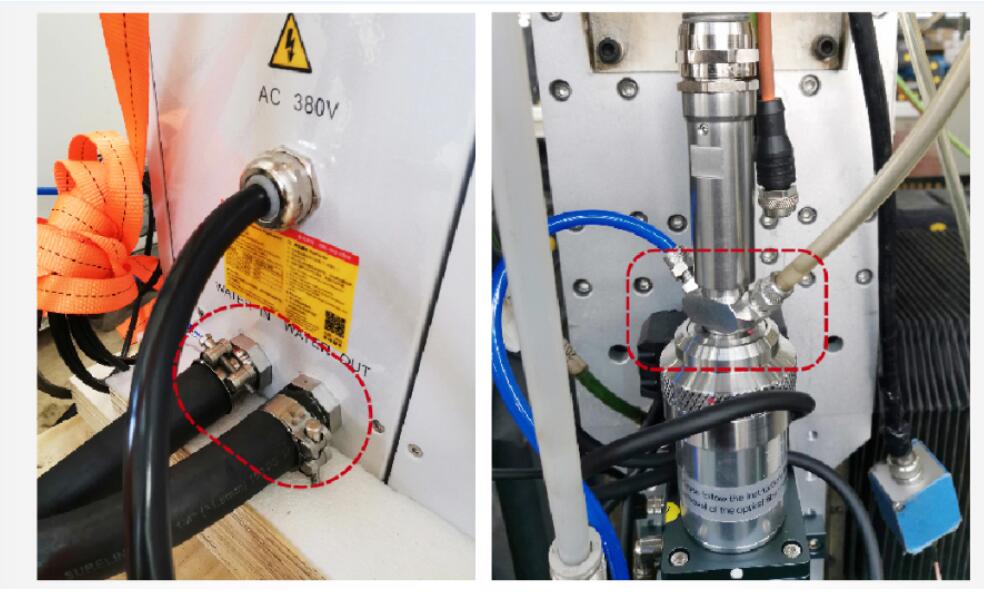

2.Maintenance for water Chiller:

Water chiller needs use High-Quality purified water or Distiled water

Change water every 15-30days.

Clean up filter every 15-30days.

if you have two weeks holidays then must remeber drain all the water from water chiller and fiber laser source.

inlcude antifreeze because antifreeze is highly corrosive.

if your weather temperature is low(below 5℃).use heating tools to blow internal pipe of water chiller to make sure without freezing.

3.Clean up water inside the fiber laser source and laser cutting head, if you don’t use machine for a long time

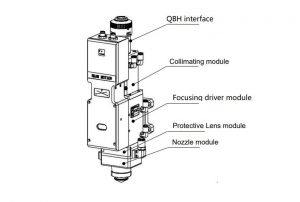

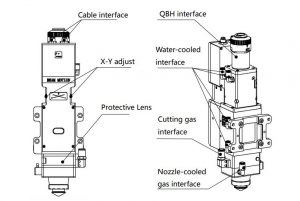

4. Maintenance for Laser Head

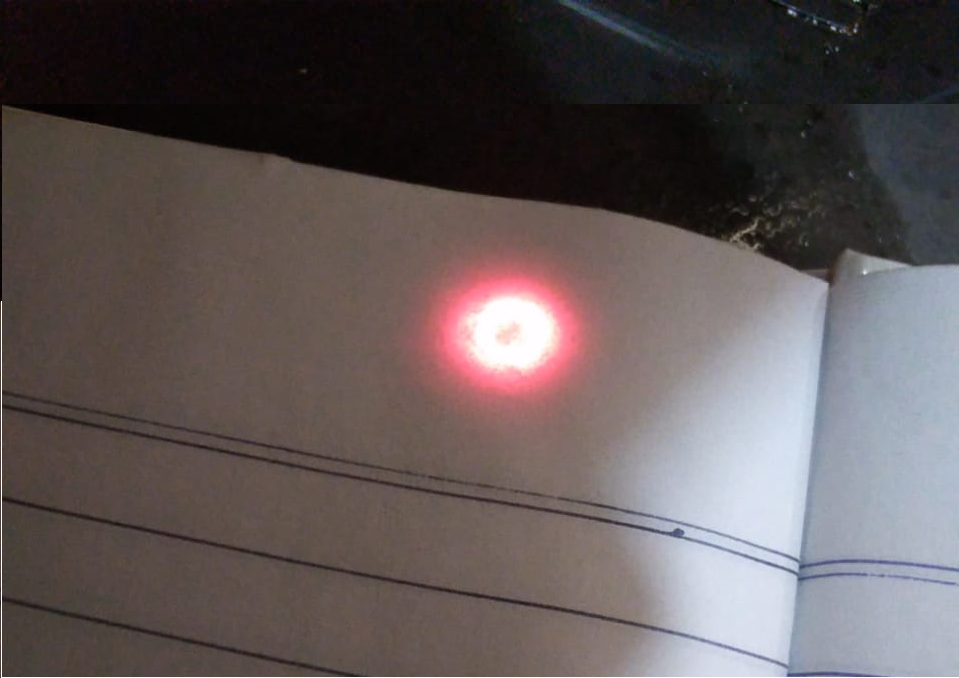

1) Check lower protective mirror before cutting everyday, whether it is dirty or damaged.

The collimating lens and focusing lens need to be cleaned once every 3 months.

Clean or change protective mirror regularly especially to Lower protective mirror.

Check protective mirror is damaged or not, after incomplete cutting or hole bursting during cutting.

2)Clean protective mirror

Tools:

Absolute alcohol + 2pcs non woven cotton swab

Procedure:

A cotton swab dipped in alcohol,Wipe the lens softly in the same direction.

The other one does not take alcohol, along the first one, in the same direction

If dirty can not be cleaned, change the mirror.

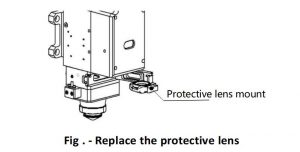

In order to facilitate the maintenance of the protective lens, the protective lens mount adopts a drawer type structure.(Fig6.1)

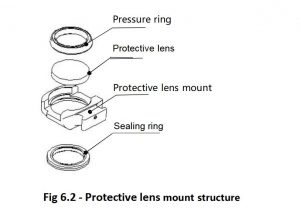

Protective Lens mount structure(Fig 6.2)

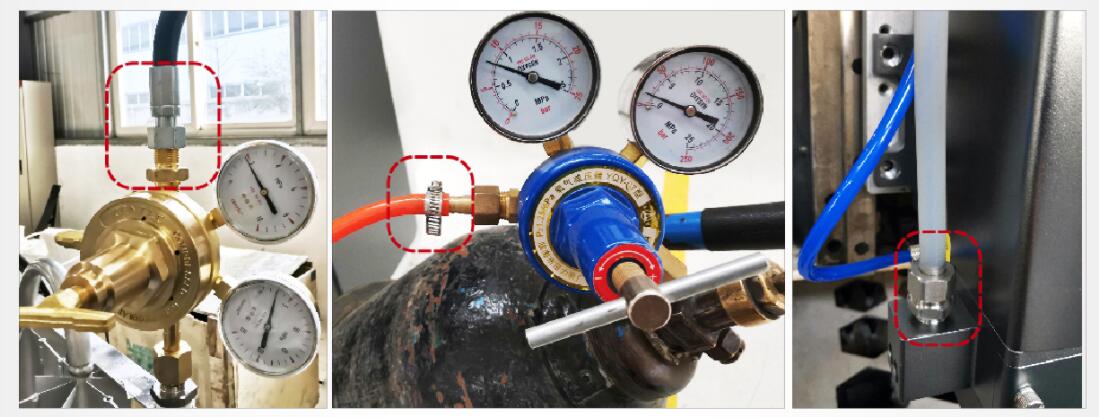

3.Check the gas whether clean regularly.

If water droplets or oil stains are found in the air pipe, stop the machine to check the filter system and clean up the dirt in the air pipe.

4. Mechanical Part maintenance:

1) When the installation is completed, the oil delivery time of the oil pump is generally 30s-60s when starting up for the first time, and check whether the oil circuit is smooth.

2) Ensure that no debris on machine table before starting the machine.

3) Keep more than 1/2 oil in oil pot. Use the gear lubricating oil.

Daily Maintenance guide for fiber laser cutting machine

(4) If weather temperature is lower than 5 ℃, you need to use warm air equipment to blow the internal pipes of the water cooler to confirm that there is no freezing;

(5)put specified distilled water into water chiller and let it stay 30minutes to make sure without water leakage.

in case,the weather temperature is lower than 5℃.need add antifreeze.

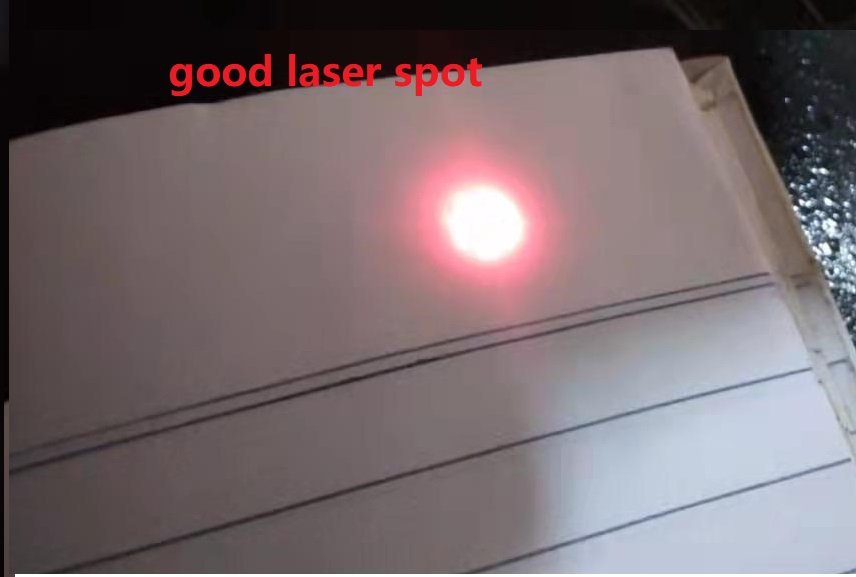

dirty lower protective lens diminished laser light–Red light dot

Clean lower protective lens make laser spot strong–red light dot