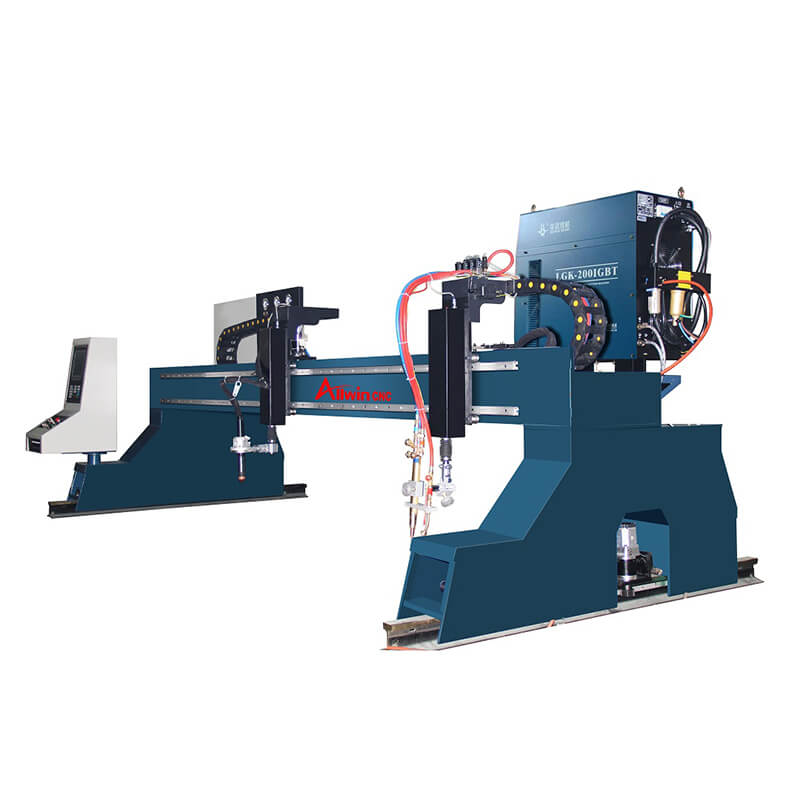

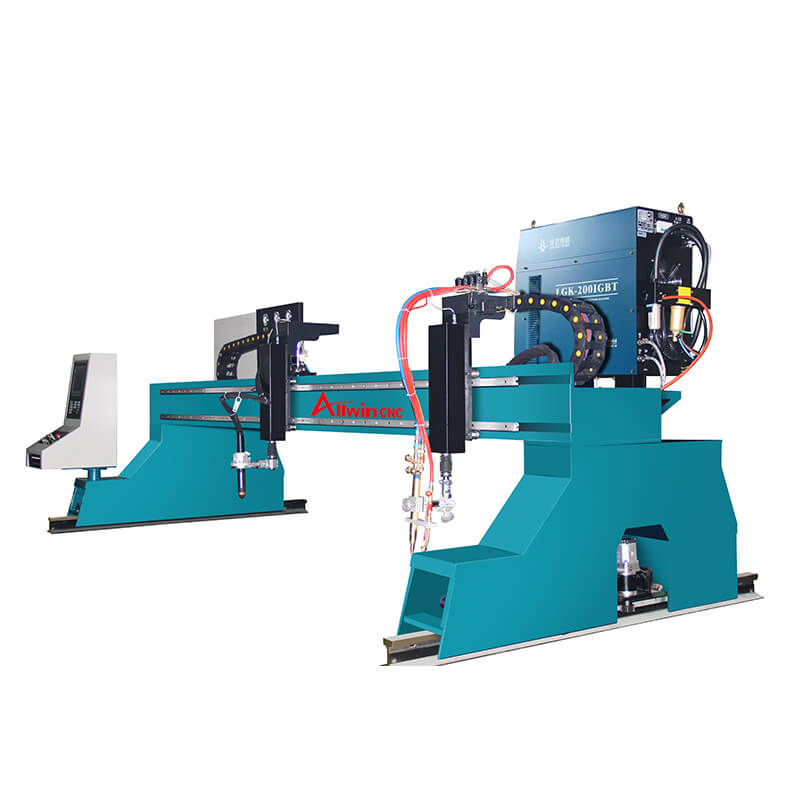

Heavy Gantry Plasma Cutting machine

- Home

- Products

- CNC Plasma Cutter

- Heavy Gantry Plasma Cutting machine

| Model: | 3060/4080 |

| Category: | CNC Plasma Cutting machine |

| Views: | 35100 |

| Brand: | allwin cnc |

| Rating: | 4.8 /5 based on 61 votes |

| Standard Price: | $3600.00 / Set |

| Price Range: | $3600.00 to $23000.00 / Set According to Configurations |

| Supply Ability: | 100 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| working area | customized |

parameter for cNC heavy gantry plasma cutting machine

| Model | 3060/4080/Customized |

| Size | 2300mm x 4000mm/3000mm x6000mm |

| Plasma Power | USA Hypertherm Power: 105A, 125A, 200A;Chinese Huayuan Power:160A, 200A,300A |

| Cutting Thickness | 0.3-80mm (According to different plasma power) |

| cutting torch | one plasma torch with one flame torch/Two plasma torch with one flame torch straight cutting oxygen torch |

| transmission mode | 24KGS Rail |

| Z lifter | Z distance is 200mm. |

| Drive Motor | Leadshine stepping motor and driver/panasonic motors and driver |

| Control System | Starfire control system with automatic height controller |

| Nesting software | FASTCAM |

| Machine Structure | General machine frame or Heavy duty frame |

| Working voltage | 220V for machine, 380V for power supply |

| Optional Parts | Rotary device, Flame head,straight flame cutting |

| Consumable Parts | Cutting nozzle and electrode |

Plasma generator LGK-300IGBT with water cooler plasma torch and autoignition flame torch

H-Beam plasma cutter Auotoatic THC height controller with 15inch touch screen in English language

why choose heavy gantry plasma cutting machine

CNC heavy gantry plasma cutting machine is an H-shaped in appearance, so it is also called H Beam plasma cutting machine, bridge plasma cutting machine.

This type plasma cutting machine is mainly used for cutting large-format metal materials, with fast cutting speed and precision High, stable operation, small deformation, good cutting effect (smooth cut, no residue). The types of metal materials that can be cut include H-shaped steel, channel steel, angle steel, etc., suitable for large-scale construction machinery, boiler manufacturing, power equipment, three-dimensional storage, shipbuilding enterprises, automobile manufacturing, steel structures and other metal processing industries.

This heavy gantry plasma cutting machine is a high-efficiency and energy-saving cutting equipment, which can greatly improve the utilization rate and cutting efficiency of metal materials. This heavy gantry plasma cuttter could work continuously for a long time without stopping.

Gantry CNC plasma flame cutting machine models are suitable for powerful mid- and high-end customers.

Gantry plasma cutting machine is the most popular CNC cutting equipment among high-end plasma cutting machines in 2021, and is well received by customers for its fast cutting speed with big working area.

2021 Best CNC Plasma Gantry Cutting Machines plasma Cutters on Sale

The CNC equipment is designed by heavy-duty H-shaped structure, the beam adopts a box-shaped welding structure, no deformation, high-efficiency bilateral drive, compact structure, fully eliminates welding stress, thick and heavy appearance, stable and reliable performance, and is currently the most standard and most versatile in the cutting machine industry. A CNC cutting machine, the beam length is 3m, 4m, 5m, 6m, 8m and othersize, all adopt bilateral drive, dual-axis core linear guide, standard configuration is 4m horizontal gauge, effective cutting range: 3.2m, longitudinal Rail length can be customized, single flame or single plasma cutting mode, with automatic ignition; it can also be equipped with flame and plasma dual-purpose cutting mode.

The attributes of the H-beam gantry plasma CNC cutting machine are as follows:

- 1. Bridge type plasma cutter with automatic height controller adopts servo motor drive and precision linear guide to ensure the stable operation and high precision of the equipment as a whole equipment

- 2. H beam plasma cutter has Wide range of applications of fine clean plasma cutter with powerful fastcam software Cutting profiles include H-beams, channel steels, angle steels, large-format steel plates, etc. The amount that can be cut includes carbon steel, cast iron, stainless steel, copper, aluminum and other non-ferrous metals. Suitable for large machinery, automobiles, shipbuilding, military industry, boilers, pressure vessels, steel structures and other metal cutting industries.

- 3. cutting carbon steel is the clean cnc plasma cutting machine with cutting gun or cutting torch with the best cutting effect in 2021. during cutting process, the amount of deformation is small, the accuracy is high, the cut is smooth, there is no residue(slags) also with plasma torch with water cooling , the cutting speed is fast, and the efficiency is high. It can be equipped with laser scanning function, the scanning time is less than 4 seconds, and there is an automatic nesting software fastcam or startcam. The nesting softare startcam or fastcam is used to improve the utilization rate of the material, reduce the material loss, realize the cutting of no residual material, and leave the long material behind for cutting.

- 4. The numerical for thc metal control system of this numerical control cutting machine adopts the working mode of infinite rotation working arm, which respectively completes the cutting of the wings and webs on both sides of the H-beam, as well as the cutting processes of perforation and locking. At the same time, in order to improve the cutting efficiency, the cutting process is divided into three processes. First, the deformation of the profile is scanned by the laser, and the cutting route is optimized according to the nesting software system, which can realize the automatic positioning, automatic error, and multi-type end of the multi-model steel with a total length of 12m. Automatic cutting process of the head.

- 5. The operation for thc plasma cutter is very easy, safe and reliable. Compact structure, overall quenching treatment, fully eliminate welding stress, thick and atmospheric shape, stable and reliable performance.

- 6. Automatic carbon steel plasma cutting machine can be produced continuously for a long time without stopping, and its capacity is equivalent to the total workload of 8-10 skilled workers, which greatly reduces labor costs and speed up working effects.

- 7.intelligent intellectualization control system could export automatic files with USB Port so that machine could read its file automatically than controlling system will order machine cut according to design.

CNC Plasma cutter Applications

Allwin Gantry plasma cutting machine is suitable for large-scale construction machinery, boiler manufacturing, power equipment, three-dimensional storage, shipbuilding enterprises, automobile manufacturing, steel structures and other metal processing industries.

China Huayuan Power

| Power supply | Cutting thickness |

| 63A | 8mm |

| 100A | 15mm |

| 120A | 20mm |

| 160A | 30mm |

| 200A | 40mm |

USA Hypertherm Power

| Power supply | Cutting thickness |

| 45A | 8mm |

| 65A | 10mm |

| 85A | 12mm |

| 105A | 18mm |

| 125A | 25mm |

| 200A | 30mm |

package and delivery for Gantry cnc plasma cutter

International Shipping Around the World

All of our cutting machines can be sent to all parts of the world by sea,

Some portable style mini plasma cutting machine could use air, international expFEDEX, UPS, etc.

We have been receiving a lots of good voice about our techincal support or stable quality.

lead time for gantry plasma cutting machine is 3 days because of in stock