Why No laser come out?why laser diminished always?

We always receive some complaints from new operator why my metal fiber laser cutting machine can not last light work?why laser diminished sharply after 10 seconds cutting?even few customers thought that we are giving them bad quality machine. please calm down if you have such condition,

please make a video shoot to record all working process so that we could help you out.

Here we would like to write article to help you&we really hope it could help you a lot.

1.first of all,check up supplying voltage 380V.if your electricity supply system could keep giving stable voltage 380V to machine

We had same condition in our workshop.two weeks ago.There are 5 cnc machine running at same time in our workshop.

One of fiber laser cutting machine always stop laser light every 1 mintues,At beginning of period,We thought that its laser generator had problem after our three engineer together check up carefully.We found that our supplying voltage is voltage shortage for 5 machine together..Then we shut off 4 machines.just keep this fiber laser cutting machine works then it works perfectly.

in all in,Giving enough stable voltage is very basically to make laser cuting machine work.

2.Cutting High-reflective material will make laser light stop.like Brass,Aluminum or gold.

How to tell what is High-reflective material?

1)Method 1: judge by resistivity

In general, resistivity of the material is smaller then the lower of the laser absorption rate (it is so called High-reflective material),

the higher the resistivity, the absorption rate is high.

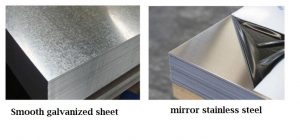

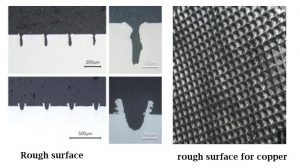

2)Method two: judge by the surface smoothness

The more smooth the surface of the material, the lower the absorption rate of laser; If smooth enough (even stainless steel), laser processing is very difficult.

The rough surface of the material has higher absorption rate;if enough rough(Even copper),laser processing is very easy.

3.Keep workshop temperature for fiber laser source

4.Check Focal path deviation or not?

Put clear tape on laser head then use 80W-100W fiber laser to dot on clear tape to make light spot in center.

for more details please check youtube.

5. Check protective lens from laser head especially to lower protective lens

make sure to have clean environment when change protective lens.Dusty would be very easy to make lens get burnt.

After finish installation use blower to blow away dust from lens.

Lower protective lens protects the focus lens from damage by the returning slags and prolong life for focusing lens.

Lower protecive lens should be replaced every 70 hours.

At the beginning, maybe needs to be changed more often Maybe 30 working hours or less

If he can use the lower protective mirror until 70 / 72 working hours, that means he operates the machine very well.

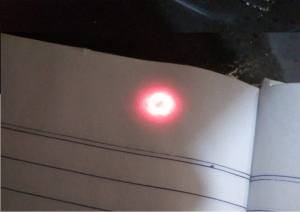

Put Laser light on A4 white paper then you would see black points insdes red light.it means that protective lens are damanged.

upper protecive lens:

If you found black point in red dot, maybe upper protective mirror dirty, then check and clean it,

If can not get it clean, you need to change new one.Normally speaking,Upper protetive lens life should be 4months.

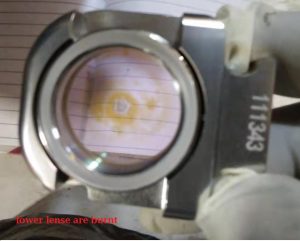

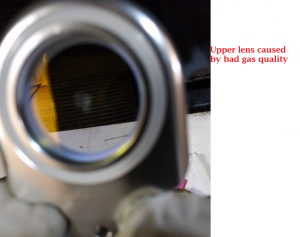

First photo is Upper procteive lens caused by dust entered into when installation or bad gas quality.

Second photo is upper protecitve lens caused by optical path deviates.(must Lock tightly to make sure connect well)

6.make sure cutting parameter is right

especially to Cutting focus,cutting speed,cutting height,cutting pressure

we will have completely parameter for your reference.Here it is a raycus for your reference.

Please contact with us if you can not fix parameter for cutting clean.

7.check Focus lens or collimating lens and QBH interface.

if cutting parameter are perfect and protective lens are fine then check up your focus lens or colimating lens.

Normally speaking for good operator..the life of focus lens could upto 6months.

last step is that Check up QBH interface.

We hope these infos could help you if you have any further question feel free contact with us.