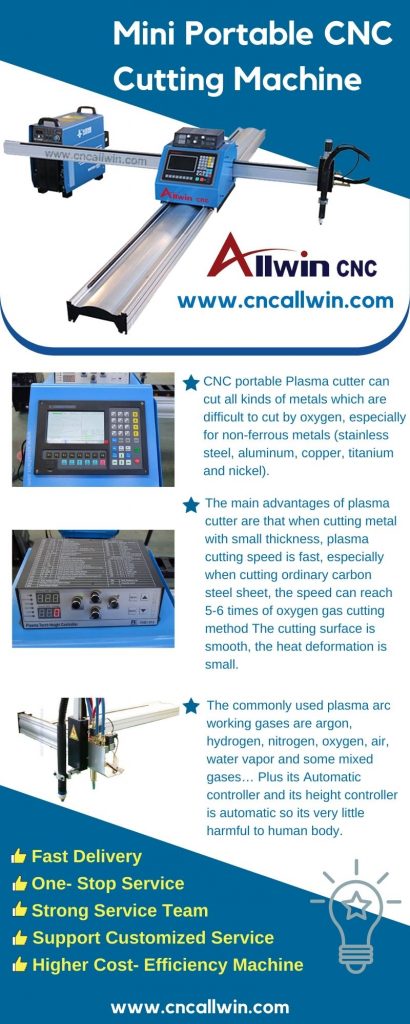

Mini Portable CNC Cutting Machine

- Home

- Products

- CNC Plasma Cutter

- Mini Portable CNC Cutting Machine

advatnage for portable plasma CNC Cutting Machine

The portable CNC cutting machine is convenient to move and carry, small in size, fast in cutting speed and long in service life. It is suitable for most small business people, DIY enthusiasts, schools, and other companies that have other metal cutting business needs.

Mini Portable CNC Cutting Machine Details

Model: | 1530 |

Category: | Minin Portable CNC Cutting Machine |

Views: | 26100 |

Brand: | allwin cnc |

Rating: | 4.8 /5 based on 61 votes |

Standard Price: | $1090.00 / Set |

Price Range: | $990.00 to $2100.00 / Set According to Configurations |

Supply Ability: | 240 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

Payment Terms: | T/T,L/C,paypal,Westunion |

China mini portable Plasma Cutting Machine Videos

Product Feature for cnc plasma cutting machine

What is Advantage of cnc mini plasma cutting machine?

1.cnc portable Plasma cutter can cut all kinds of metals which are difficult to cut by oxygen, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium and nickel).

2. The main advantages of plasma cutter are that when cutting metal with small thickness, plasma cutting speed is fast, especially when cutting ordinary carbon steel sheet, the speed can reach 5-6 times of oxygen gas cutting method The cutting surface is smooth, the heat deformation is small.

3. The commonly used plasma arc working gases are argon, hydrogen, nitrogen, oxygen, air, water vapor and some mixed gases… Plus its Automatic controller and its height controller is automatic so its very little harmful to human body.

| Model | 1530 |

| Size | 48″ x 96″ |

| Plasma Power | USA Hypertherm Power: 45A, 65A, 85A, 105A, 125A, 200AChinese Huayuan Power: 63A, 100A, 120A, 160A, 200A |

| Cutting Thickness | 0.3-50mm (According to different plasma power) |

| Minimum Cutting Diameter | Depend on cutting thickness |

| Max Cutting Speed | 12m/min |

| Transmission | Taiwan Hiwin Square rail and Rack transmission |

| Drive Motor | Leadshine stepper motor and driver |

| Control System | FANG LING control system with THC |

| Machine Structure | Aluminum Alloy Structure |

| Working voltage | 220V for machine, 380V for power supply (63A with 220V i) |

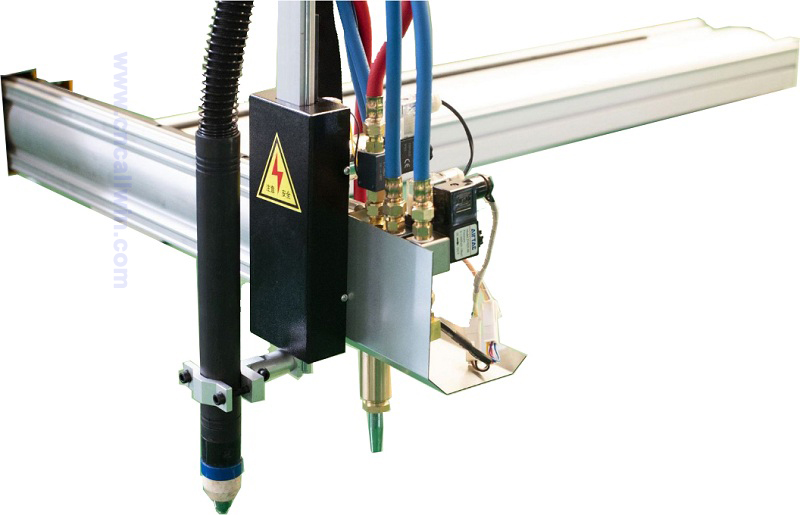

| Optional Parts | Rotary device, Flame head |

| Consumable Parts | Cutting nozzle and electrode |

Cutting capability of plasma cutting machine

How to choose plasma generator?

For CNC plasma cutting machines, how the cutting effect or how cutting thickness have a great relationship with the plasma power supply.

Different brand plasma generator has different cutting capacity.

Under the same working environment, different models of plasma cutting machine power supplies have different maximum cutting thickness and optimal cutting thickness; generally, the greater the power of the plasma power supply, the higher the optimal cutting thickness and maximum cutting thickness.

For low carbon steel, the optimal cutting thickness range of plasma cutting machine is 1mm to 60mm; the maximum cutting thickness is between 1mm and 100mm. The maximum cutting range of stainless steel is between 1mm and 50mm. The cutting thickness of aluminum material is 1mm to 50mm

To give you right CNC machine with plasma generator,the user need ask suppliers before order..for details cutting thickness for plasma cutting machine please take reference as below parameter sheet.

Related China metal cnc plasma cutter

maintenance of plasma cutting machine

How to maintain the portable cnc plasma cutting machine?

The maintenance of plasma cutting machine is relatively simple, usually do the following maintenance work:

1. Do not use and store the cutting machine in strong sunlight.

2. Do not use or store the cutting machine in a humid environment.

3. When the cutting machine is in use, its ventilation holes shall not be blocked.

4. The cutting machine should be used and stored in a well-ventilated environment.

5. Open the housing case at least once a year and clean the dust and metal chips inside the machine with dry compressed air. 6. Check regularly whether all cable insulation skins of the cutter are damaged, and wrap or replace the cable if damage is found.

7. Check regularly whether there is any loose part in all electric connection parts, and fasten the loose part. 8. Regularly release the water and impurities accumulated in the filter pressure reducing.

We have a strong professional technical team to provide the best products and service for these metal plasma cutting machine..it is the best proper choice if you are working on metal industries.

We have experienced managers with the most perfect price system integration schemes for our customers.

Established business partner with many customers from Russia, Ukraine, U.S., Japan, South Korea, Canada, Italy, Turkey, Iran, Iraq, Egypt, Brazil, Pakistan etc. more than 50 countries.

We have been experienced in exporting the CNC Plasma machine for over 7 years, familiar with the different requirements from all kinds lines

Meanwhile, we insist the principle of “the best products, the most reasonable price, the maximum benefits for customers”, there are prestigious fame in the industry business field.

All response and suggestion from you, we promise to give you a satisfactory reply in 12 hours.

package and delivery for our cnc plasma cutter

All of our export machinery and equipment adopt standard plywood boxes after high temperature and high pressure treatment. The boxes meet the inspection standards of the United States and the European Union; the transportation method can be transported by plane, ship, or train according to customer requirements.

We have our own long-term cooperation transportation company, which will give us more favorable prices and feasible suggestions in transportation prices, which will minimize the customer’s freight expenses, and there will never be overcharges.

we here provide you one-stop solution for metal industries cnc machine at affordable price